|

Flathead Ford Valve Removal Tools |

||||

|

|

||||

|

Home Parts Drawings Web Links Tune-Up & Service Serial Numbers Engine ID Trans ID Model Identification Terms of Sale Contact Us Our Online Store Our Catalog |

How to Remove Those Stubborn Valves and Valve Guides - Page 2 | |||

|

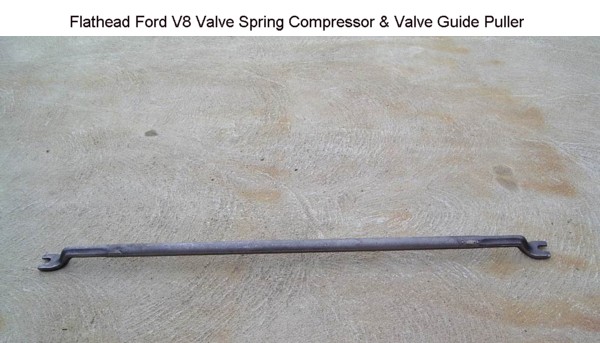

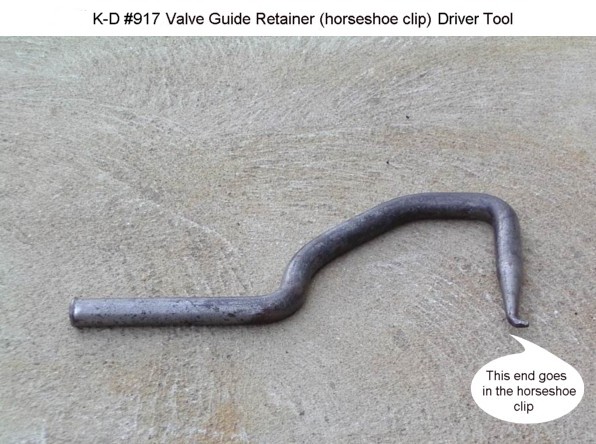

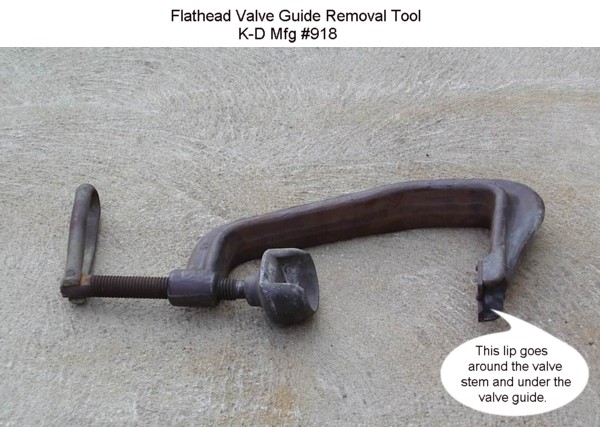

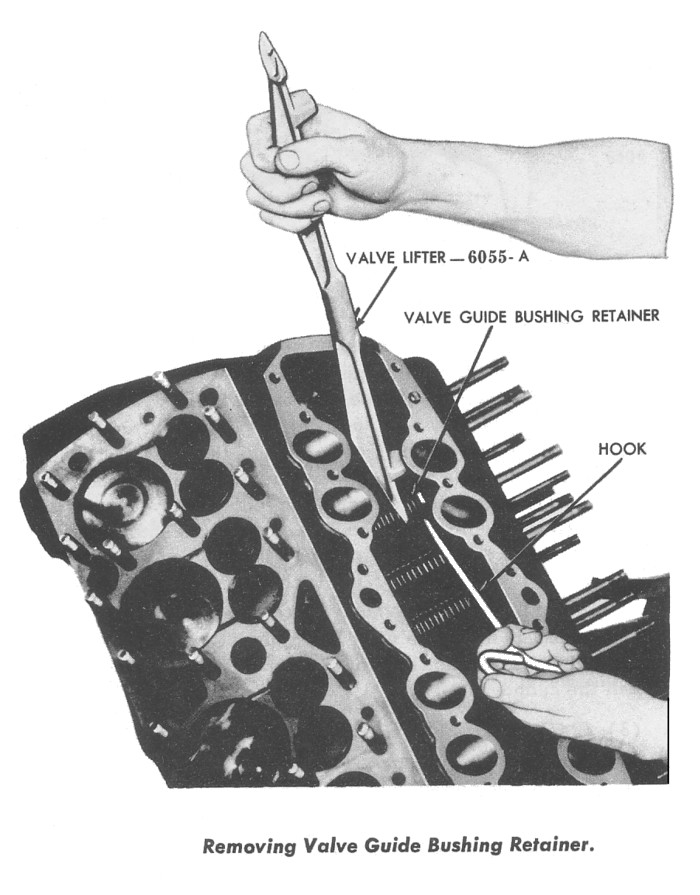

The general sequence of removal for these parts is to first use the long spring compressor bar (also called a "pickle fork tool" - see picture A) as a lever to compress the valve spring upward. This should let the valve spring retainer and lock to loosen. Usually, one can pop these out with a screwdriver while compressing the valve spring. To make things easier you can use a common C-Clamp type valve spring compressor to compress the spring upward. This leaves you with two hands to "encourage" the valve lock out. You will also be saved the fatigue of holding the spring compressed with the pickle fork type tool as your other hand tries to get the valve lock out. The next steps are where things can get difficult. The idea is to force the valve guide down to allow the valve guide retainer (horseshoe clip) to be pulled out. The valve guides have a small groove machined into their lower end to allow the pickle bar tool's small forked end to engage it and pull the guide downward. You only need it to move down a slight amount....enough to let the horseshoe clip to be pulled out. This clip slips over another groove higher up on the valve guide and actually rests in a slight recess near the "roof" of the valve galley. Sometimes, despite all your best efforts to pull the guide down with the pickle bar tool, it won't move at all, or not enough to let the horseshoe clip come out. This is common on engines that have had water leak into the block or had a crack in a water jacket. Rust will hold the valve guides almost like they were welded in there. There is an old mechanics tool (not shown here) that has a bend in it and fits around the head of the valve. The end of it rests on the top of the valve guide. You hit this tool with a hammer and it drives the guide downward, freeing up the horseshoe clip for removal. This is only useful, of course, if you can get the valve to move up enough to fit the tool under and around the valve head. A nice tool for removing the valve guide retainers (horseshoe clips) is the simple "C" shaped K-D impact tool (see picture B) with the small pointed end. There are several different tools for pulled the clips out. I think this was the best one in terms of effectiveness for the most stubborn retainers. Some use a prying action, like a lever. This tool is shaped to let the pointed end reach into the galley and engage the small hole in the retainer. Use a heavy glove to save your hands and fingers. Take a heavy hammer and strike the top end of the tool. It generally takes anywhere from 4 or 5 to 10 or more accurate blows to literally drive the clip down and out. Don't try to drive the clip out in one heavy blow. Let the hammer hits do the job properly without damaging anything else. Of course, the retainer is damaged beyond use by this action, but they are cheap and readily available from most suppliers. Another tool (shown below - see picture C) basically forces the valve guide up from below by a screw action. Its top cup surrounds the valve, allowing upward movement of the assembly. Obviously, the valve guide retainer (horseshoe clip) MUST be removed before this tool can be used. You can usually make the lower slotted end catch the bottom of the valve guide thru the spring, but it's easier if you remove the valve spring. Tightening the handle forces the guide up......they usually come up with a pop! It doesn't shoot out, but pops up about a 1/4" .....enough to simply pull the assembly out with your fingers. If the guide was rusted into place, it should move up slowly (if it moves at all) and will be hard to get moving. For information on purchasing the valve guide bar tool click here Note: Except for the valve guide bar tool, we do not sell any of the other valve tools pictured or described in the following tech articles about valve removal or installation. The tools pictured were manufactured many years ago and have not been produced in recent years. You can sometimes find the older tools at swap meets or vendors who specialize in the old tools or in other online shopping venues. |

||||

|

Picture A

For information on purchasing the valve guide bar shown above, click here. |

||||

|

Picture B

|

||||

|

Picture C

|

||||

|

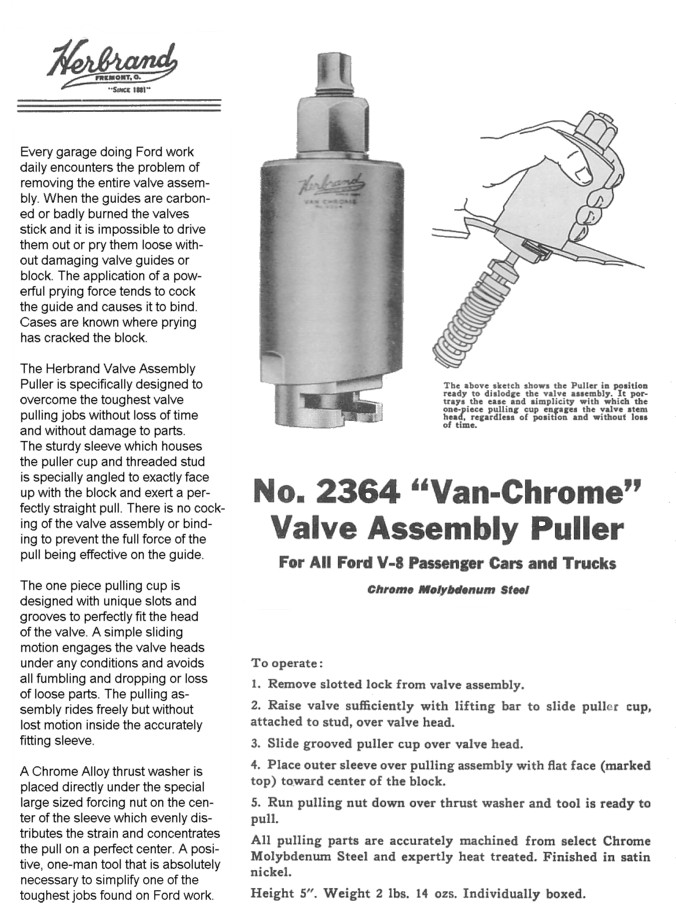

Picture D Here is a copy of a catalog page

in an old Herbrand Tool brochure. This is another ideal tool for removing |

||||

|

Picture D

|

||||