|

Ford

Top Loader Three Speed Transmission |

|

|

Home

Parts

Drawings Web

Links Tune-Up

& Service Serial

Numbers Engine

ID Trans

Identification Model

ID Terms

of Sale Contact

Us Our

Online Store

Our Catalog |

|

Potential

Problems with Transmission Popping Out of Gear

|

|

This is practically the

number one complaint on early Ford (1939 and newer) three speed

transmissions. The most common symptom is that the trans is popping out

of 2nd gear under deceleration. This action generally occurs while in

second gear and the driver lets off the gas (reducing power to the

driveline) and will happen most frequently as the vehicle is going down

a hill in second gear. Because

the 1932 and newer transmissions had the helical cut gear teeth for

second gear, there is an axial thrust load on the gearset. In other

words, the gears tend to push themselves toward the front or the rear of

the gearbox, depending on the driving conditions. What happens is that

the connection between the second gear (7102 in the drawings) and the

synchronizer sleeve (7106 in the drawings) moves apart under

deceleration. The splines inside the sleeve will disengage from the

synchro teeth on the gear. There is a small amount of spline-to-tooth

engagement (about 1/8" from front to rear) so a relatively small

amount of slack in the transmission parts will allow that disengagement

movement. There are

multiple reasons for this slack and the rebuilder must evaluate each

possibility for any contribution to the problem. Let's look at each

point and how it must be addressed. These transmissions are typically 60

to 70 years old with many miles on them. They may have been poorly

maintained over their lifespan. They may have been abused by various

drivers over the years. They may have had inadequate or improper

rebuilds during their life, so finding the root cause may involve more

than one single issue. The

1932 to 1938 type transmissions used an early version of a synchronizer

assembly. Some details relating to the endplay of second gear will be

different from the 1939 and newer type.

|

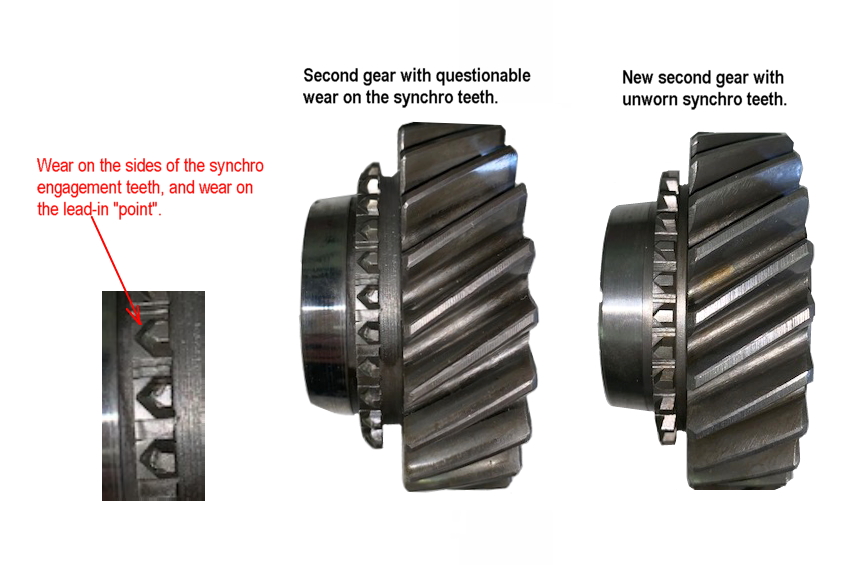

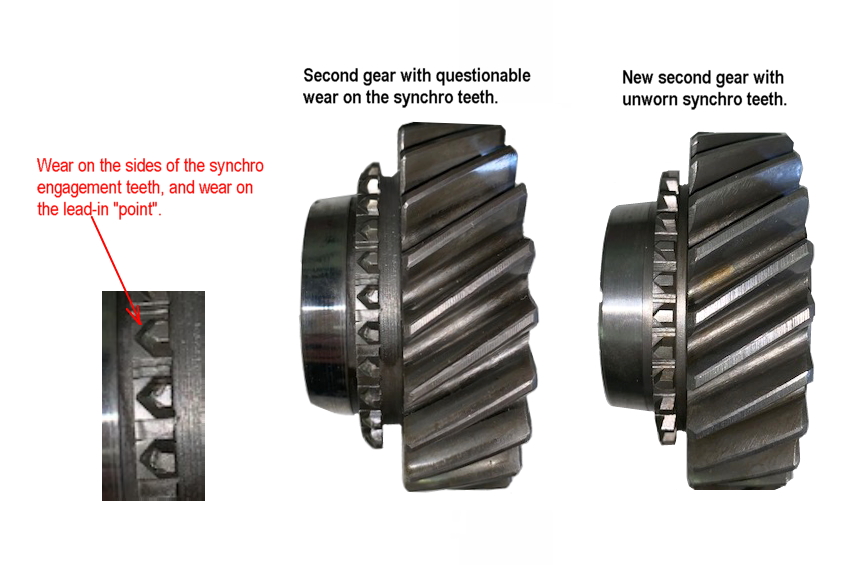

- Worn Second Gear: The

7102 second gear (located on the mainshaft) has 30 small synchronizer

engagement teeth. These teeth will have parallel sides of about

1/8" apart, and have a pointed tip that faces the synchronizer

sleeve. As the gear wears, there will be a loss of tooth width and the

pointed end will become rounded off. This leaves less tooth to grasp

and hold into place. Also, the internal bronze bushing used on most of

these gears will eventually wear to the point that the gear can rock

slightly on the mainshaft, tipping some of the synchro teeth even more

out of alignment. This bushing was manufactured into the steel gear

and was never sold as a service part. If the bushing or the synchro

teeth are well worn, the gear must be replaced. Some variations of

these gears were made with an exact ground and finished inside bore,

and did not come with a soft bushing insert.

|

|

|

-

Excessive Endplay in the

Gearset: Mainly, this involves movement of

second gear on the 7061 mainshaft, but also includes movement of the mainshaft

in the gearbox case. When second gear and the synchronizer assembly are

installed on the mainshaft, their movement is limited by the shoulder at

the front of the spiral splines on the mainshaft, and the lock ring

(7059) placed in its groove just in front of the synchro hub. This

movement is supposed to be limited to 0.004 to 0.008" and is

checked with a feeler gauge after the two components (and any required

spacer washers) are fitted in place. It is best to keep this clearance

(or endplay) to the minimum 0.004" as much as possible. Various

spacing washers are available to limit this endplay.

-

The

transmission input shaft (7017 main drive gear) and output shaft (7061

mainshaft) are controlled to their exact locations by their ball bearing, the

snap ring on each bearing, and the front & rear bearing retainers

(7050 and 7085). When the mainshaft (which carries second gear) is

allowed to drift toward the rear of the gearbox, the 2nd/high shifter

fork is going to hold the synchro sleeve (7106) in its normal

position.....and the drifting action will carry second gear and the

mating synchro teeth further away from each other. There are two details

to watch in controlling this problem. First is the correct snap ring

(7070) on the rear ball bearing. This retaining ring is supposed to be

0.075 to 0.077" thick. A used ring should never be reinstalled on a

bearing as the ring will be worn in its inner face (where it fits into

the groove of the bearing). Many aftermarket suppliers of snap rings do

not have the correct thickness for this ring. Be sure to use a new ring

of the correct thickness here. Also, the front (7051) and rear (7086)

retainer gaskets should not be excessively thick or the gasket will hold

the bearing retainer away from the case, allowing the ball bearing to

travel toward the rear. The correct gasket thickness should be

approximately 0.014 to 0.016" thick. A simple test for shaft

endplay is to push-pull the shaft with your hand.....after you have

installed the shaft with its bearing, snap ring, and bearing retainer in

place. On closed drive transmissions, you will have to install the

universal joint on to the mainshaft. You have to grab the front half of

the U-Joint to push-pull the shaft assembly. Any visible movement

front-to-rear, which you will be able to feel and perhaps see, will

indicate the possibility of excessive endplay. Recheck the assembly and

fit of everything to determine the problem.

-

The 1932 and

newer three speed transmissions generally had an oil baffle (7080)

located on the back end of the mainshaft (7061) just ahead of the rear

ball bearing. It is important that the correct baffle is in place as it

also positions the mainshaft on its final assembly position.

|

-

Worn Shifter Fork: The

2nd/high shift fork (7230) can be badly worn at the fork tips. This is

usually evident by a curved wear pattern at the point where each tip

fits into the fork groove of the synchronizer sleeve (7106). The fork

can also be worn in the upper slot where the shifter lever makes contact

with the fork for front-to-rear shifting action. In either case, if a

new or good used fork is not available, you will have to weld up the

worn areas to restore them to the original dimensions, and carefully

grind or file the welding to make as smooth a fit as the original.

|

-

Worn Shifter Lever: In

the case of the toploader three speed transmission, the shifting lever

(7210) has a small nub about 2" up from the bottom tip, which is

the actuating portion for the 2nd gear shifting fork. As with the fork,

a welded repair will work if a new or good used lever is not available.

The nub is 0.501" in diameter. The normal wear will occur at the 3

o'clock and the 9 o'clock positions on this nub.

In the case of a side loader transmission, check the adjustment of the

two shifter rods as one or both might not be placing the transmission

fully into a gear position. Set the shifter lever (at the steering

column) in neutral and secure it there. Remove the shifter rods at the

ends with the adjustable clevis. Place the gearbox shift levers into

their respective neutral detent positions. Re-position each shift rod

onto its own shift lever..........adjust the threaded clevis to raise or

lower the rod until it aligns and fits into its lever without having to

push or pull it into place. Tighten the clevis lock nut and repeat the

same adjustment on the other shift rod. Replace any worn bushings in the

shifter rods if needed.

|

-

Other Things to Check:

There can be other factors contributing to the popping out problem. In

no particular order, consider these potential issues:

-

Badly worn

(or even missing) pilot bearing, allowing the input shaft & gear to

wander out of alignment

-

Gearbox case

not bolted tightly to the engine bell housing, or something keeping the

gearbox out of alignment to the engine.

-

Broken caged

roller bearing (7118) in the back pocket of the 7017 main drive gear,

allowing the 7061 mainshaft to drop out of alignment.

-

Incorrect

rear bearing retainer. Some early truck retainers do not come with the

retaining ring cast into the retainer, and have been mistakenly used in

place of the correct B-7085 retainer and B-5099 plate that is

supposed to be used on the 1932-36 three speed rear supports.

|